Share This Story

The manufacturing sector is undergoing a renaissance, fueled by rapid technological advancements and a renewed focus on domestic production. With an estimated 4.6 million jobs needing to be filled by 2028, many requiring specialized skills in robotics, AI and automation, the workforce gap is ever widening.

The future of advanced manufacturing demands highly capable collegiate training spaces.

At Guilford Technical Community College (GTCC), this concept is becoming reality through the creation of the North Carolina Federation for Advanced Manufacturing Education (NC FAME)—a project that demonstrates how future-focused planning and intentional design can integrate advanced technology while also meeting the needs of both students and industry.

Partnering with Industry to Shape the Future of Learning

Effective manufacturing education and training facilities must reflect the industry’s diverse and continuously evolving needs. In addition to working closely with institutional leaders and faculty, our Higher Education practice team often works closely with local industry partners and community stakeholders from the earliest stages of the design process to ensure each facility supports real-world learning objectives.

The vision for GTCC’s NC FAME program was born from strong partnerships with industry leaders like MasterBrand Cabinets, Toyota, Procter & Gamble and Smurfit Westrock.

Key takeaways from this collaborative design process include:

- Proactive Equipment Planning: Designing with future equipment needs in mind to reduce costly, disruptive modifications later

- Optimized Layouts: Balancing floor space with operational needs, ensuring sufficient room for machinery, serving and workflow

- Enhanced Acoustic Strategies: Incorporating sound control measures to foster focused learning within high-noise environments

- Open-Volume Areas: Creating spaces that mirror the workforce while enhancing accessibility, flexibility and vertical efficiency

- Support Zones: Integrating quiet classrooms and relaxation spaces for relief from the high-energy training areas

Adaptable Spaces for an Evolving Industry

The pace of change in advanced manufacturing demands learning environments that are as agile as the industry itself. Students and employers alike benefit from spaces that can accommodate a diverse range of programs, technologies and equipment—all while remaining adaptable to future advancements.

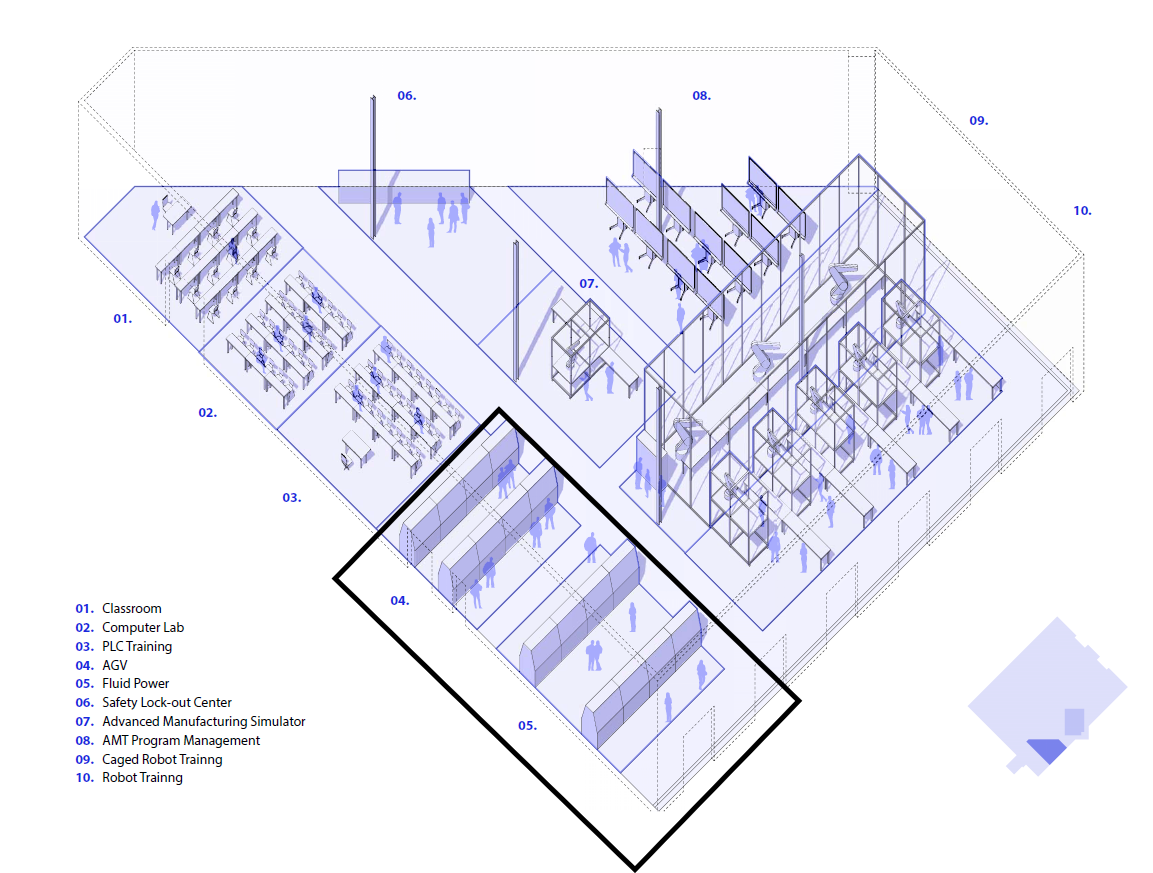

The NC FAME facility at GTCC exemplifies the power of flexible design. Integrated training zones will support everything from robotics and mechatronics to fluid power and automation, with modular components allowing spaces to transform in minutes.

Key design elements include:

- Reconfigurable Utility Walls: Integrated power and air systems designed to be repositioned easily, minimizing downtime and maximizing versatility

- Mobile, Multi-Use Furniture: Lightweight, wheeled furnishings and equipment empower students and instructors to rearrange layouts for various training scenarios

Integrated Systems for Seamless Technology Support

Advanced manufacturing spaces must support complex equipment and digital learning tools. In GTCC’s NC FAME facility, integrated systems will ensure that technology is reliable, accessible and ready to evolve alongside the industry.

Key features include:

- Advanced Building Systems: Robust power and air delivery systems are designed to support high-demand equipment, robotics and hydraulic fluid power

- Scalable Infrastructure: Electrical conduits and panel systems anticipate expansion, ensuring the facility can support emerging technologies without retrofitting

In the NC FAME facility, systems like this mechanical training station will be supported with the necessary power and air infrastructure, ensuring they’re ready for use from day one.

Preparing Students for a Competitive, Global Workforce

With over 40% of manufacturers planning to adopt AI and automation technologies over the next five years, institutions that invest in forward-thinking training environments will lead the way in workforce preparation. By designing flexible, technology-empowered learning environments and fostering strong industry partnerships, CPL is helping higher education clients like GTCC equip students with the practical skills needed to thrive in an evolving global marketplace.

We believe that the manufacturing leaders of tomorrow are built in the classrooms and labs of today. Together, let’s design the future of advanced manufacturing education.