Share This Story

In recent years, the state of Georgia has observed a growing need for skilled tradespersons in advanced manufacturing and emerging technologies. To support these needs, the Technical College System of Georgia (TCSG)—a leader in the state’s workforce development and adult education programs—commissioned a new Center for Advanced Manufacturing and Emerging Technologies (CAMET) at Chattahoochee Technical College, the largest technical college within the TCSG and one of CPL’s longest-running client partnerships in Georgia.

Following extensive programming and visioning sessions with key stakeholders from the TCSG, Chattahoochee Tech, and the Georgia State Finance and Insurance Commission (GSFIC), the vision for CAMET emerged. Having previously designed a wide range of projects for Chattahoochee’s North Metro campus, as well as other TCSG campuses, CPL was well-equipped to execute this state-funded project.

In order to promote cross-curricular collaboration, cooperative learning and adaptability, final designs for the new building featured contemporary classrooms and interiors with dedicated areas along public corridors for student gatherings and private study, as well as three flexible laboratory spaces that can be subdivided as needed. Mindful of life-cycle cost and sustainability, CPL ensured the design incorporated Georgia’s Energy Efficiency and Sustainable Construction Standards for State Buildings.

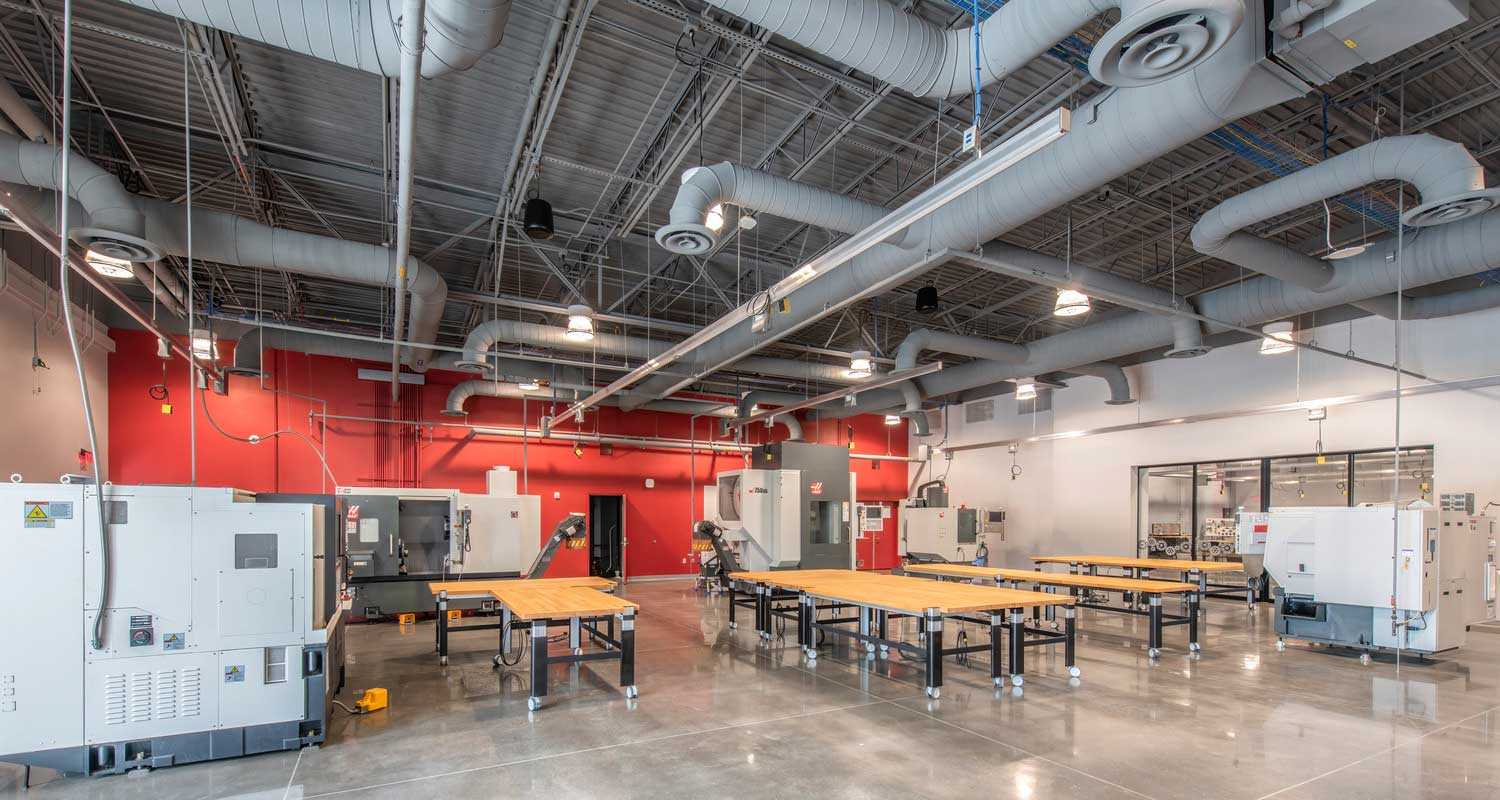

Key program elements included space for high-tech industrial maintenance, robotics and advanced machining laboratories; multipurpose workspaces with adjoining classrooms; computer laboratories; faculty offices; and conference rooms.

The building’s design and layout grants CAMET professors the ability to monitor student activities in both classrooms and laboratories—an instrumental aspect in maintaining a safe, communal learning environment. With glass walls and roll-up, garage-style doors, a direct line of sight between the laboratories was created, fostering a sense of connectivity throughout the entire facility.

Additionally, the layout integrated a wide range of modern accoutrements, including charging stations, video display boards and efficient building systems that support the instructional mission of the Center, all to keep step with the evolving mechanical technology landscape.

“Advanced manufacturing and technology are not static, so by design, CAMET is highly flexible to accommodate future manufacturing techniques, shifting teaching pedagogies and changes in the ways students learn,” explained K. Scott Gordon, AIA, NCARB, LEED AP, Principal at CPL. “Dr. Ron Newcomb [President of Chattahoochee Tech] challenged the team from the start to be mindful of the future, and we believe the design and layout provides students at Chattahoochee Tech a future-ready facility that will also serve them—and the community—well today.”

True to their interpersonal and engaging work approach, in addition to sharing hand-drafted illustrations, the project team invited stakeholders to explore detailed virtual reality (VR) walkthroughs generated by CPL’s Creative Labs team. The opportunity to immerse themselves into the conceptual spaces provided college officials with a greater sense of understanding and more succinctly communicated the building’s prospective “look and feel,” which streamlined the design process for all involved parties.

Completed in 2022, the $10 million CAMET facility is now home to the college’s Precision Machining and Manufacturing program and the Industrial Maintenance and Electrical Technology program, offering credit and non-credit courses in robotics, aerial vehicle manufacturing and other emerging technologies. The Center is poised to help current and prospective students across Chattahoochee Tech’s northern Metro Atlanta service area eagerly pursue careers in skilled trades through higher education for decades to come.